RT welding machine

Product description

Fiber laser welding machine adopts continuous fiber laser integrated structure, through the fiber output laser generated by the laser, and then with the supporting table, to achieve all kinds of welding operations. It can meet the needs of precision welding, and has many advantages in continuous welding state. It is suitable for most laser welding fields.

Product features

1, high standard and high configuration, high-end fiber laser, double temperature and double control water cooling heat dissipation, original imported fiber.

2, high electro-optical conversion rate, high energy efficiency ratio, no pollution. Green environmental protection, suitable for industrial production.

3, scientific design, high integration, 24h full load operation, uniform and consistent welding effect.

4, CNC high precision worktable, can weld any plane graphics, welding speed, high welding strength.

5, sealed cabinet, the whole cabinet to achieve dustproof design, safer operation.

Detailed description

The laser generated by the fiber laser is output through the fiber, and is matched with the supporting workbench to complete the corresponding welding.

Fiber laser is divided into pulse fiber laser and continuous fiber laser. The pulse fiber laser can adjust the single point energy of laser pulse by setting the peak power, frequency and pulse width of laser. The continuous fiber laser can adjust the output laser power by setting the average laser power.

The equipment uses continuous fiber laser integrated structure, with the role of safety protection and environmental protection, with fully enclosed welding cabinet, compact structure and high integration. Gantry type welding mold loading blocks multi-dimensional adjustment of laser welding head, two-dimensional horizontal CNC high-precision worktable, with special fixture to meet the requirements of precision welding.

Fiber laser has the characteristics of high beam quality and high energy. In the continuous welding state, compared with the same power YAG laser, it has the characteristics of deep welding depth and good welding strength. At present, it can be suitable for most laser welding fields.

The laser adopts continuous fiber laser, the laser adopts integrated structure, it has the role of safety protection and environmental protection, can work normally in various environments.

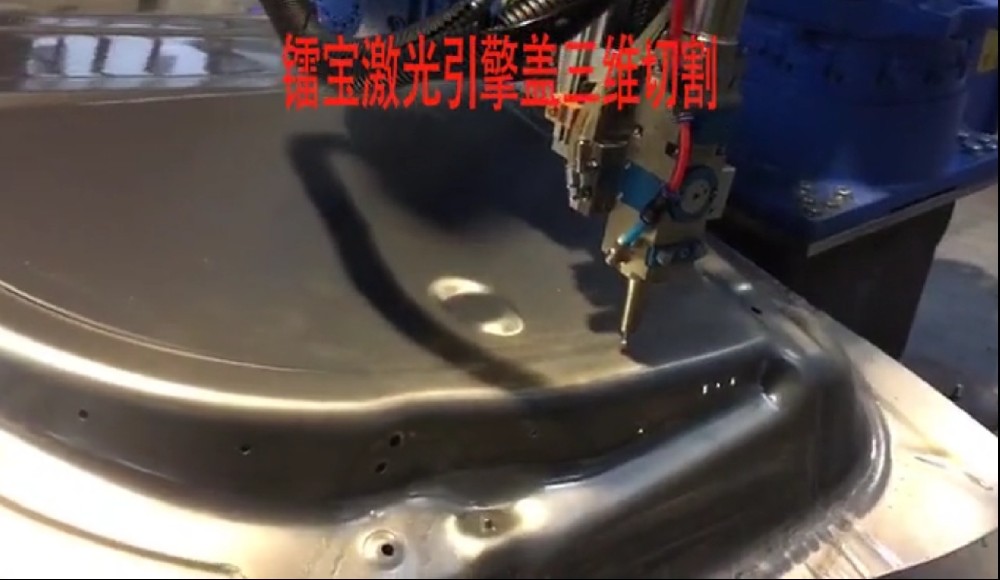

Fiber laser welding machine is a kind of laser welding equipment that couplings the high energy laser beam into the fiber, transmits it for a long distance, and then focuses the parallel light on the workpiece through the collimation mirror. For the parts that are difficult to be welded, flexible transmission non-contact welding is implemented, which has greater flexibility. At present, it is used in sheet metal manufacturing, battery sealing, auto parts and other industries. Optical fiber transmission laser welding machine laser beam can realize time and energy splitting, can process multiple beams at the same time, provides conditions for more precise welding.

Optical fiber transmission laser welding machine, unique optical system design, stable optical performance; Reasonable power design, small occupation space, optional built-in water cooler; Small light spot, good penetration, has a unique advantage in precision welding industry; Imported quartz and imported coating technology are selected for optical lens, with high damage resistance threshold and stable beam quality. Unique energy feedback technology, can accurately control the energy of each laser point, effectively ensure the uniform and consistent welding effect.

Sealed cabinet: the whole cabinet to achieve dustproof design, save space;

Routine maintenance is simpler

Modular design, easy to achieve functional expansion. Can realize spot welding, butt welding, overlapping welding, sealing welding and so on

Red focusing/indicating, precise control, small focusing spot, high precision positioning;

Ability to work steadily for a long time, especially suitable for three shifts.

Self-diagnosis, protection and warning function;

Provide a variety of special industry fixture and control mode, the system is easy to realize and automatic production line matching.

Fine spot, beautiful weld, welding strength;

High frequency, fast welding speed, production efficiency can be greatly improved;

High integration, stable operation, high product qualification rate;

With customized welding table, automatic welding;

Low operating cost, less consumables, free maintenance.

The laser beam quality is good, the welding speed is fast, the welding seam is firm and beautiful, and the welding scheme is efficient.

Industrial PC control, the workpiece can do plane trajectory movement, welding points, straight lines, circles, squares or lines and arcs composed of any plane graphics.

High electro-optic conversion rate, low energy consumption, long-term use can save a lot of processing costs for users.

High reliability equipment, can be 24 hours continuous and stable processing, to meet the needs of industrial mass production processing.

Special aircraft customization ability, can be tailored to customer needs to create exclusive models.

Applicable field

Used in sheet metal manufacturing, battery sealing, auto parts, precision machinery, hardware products, medical equipment, sensor industry, auto manufacturing, clock precision parts and other industries. Mainly used for continuous welding of copper, aluminum, titanium, stainless steel, low carbon steel and other metal sheets.

Technical parameters

Model | RFL-W500S | RFL-W1000S | RFL-W1500S | RT-FL-W2000S |

Center wavelength | 1080nm | |||

Control mode | Continuous/pulse modulation | |||

frequency modulation | 200-50KHz adjust available | |||

Average output power | 500W | 1000W | 1500W | 2000W |

Beam quality | M2<1.1 | M2<1.15 | M2<1.2 | M2<1.2 |

Max penetration | Stainless steel:<1.2mm/ Carbon steel:<0.8mm | Stainless steel:<2.0mm/ Carbon steel:<1.5mm/ aluminum:<1.0mm | Stainless steel:<3.0mm/ Carbon steel:<2.0mm aluminum:<1.5mm | Stainless steel:<4.0mm/Carbon steel:<2.5mmmm aluminum:<2mm |

Fiber output port | QBH | |||

Energy instability | < | |||

Beam diameter | 5-7mm | |||

Voltage | AC220V | AC220V | AC380V | AC380V |

Cooling way | Double temperature double control water cooling | |||

Max power consumption | 4KW | 6KW | 9KW | 12KW |

Operating temperature | temperature:0-40 humidity<70%,Non condensation | |||

Fiber length | 5-15M | 5-15M | 5-15M | 5-15M |

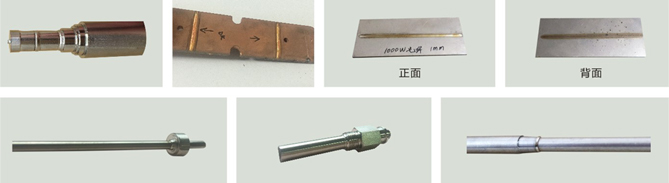

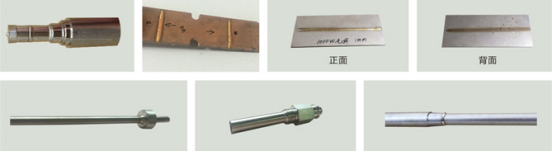

Sample display

CN

CN English

English