RT welding machine

Product description

Mold laser welding machine, also known as mould laser repair machine, is designed for the mould industry, the introduction of international advanced technology, suitable for precision injection molding, die casting and other large, medium and small mould repair welding. Laser mold welding can avoid the heat strain and post-welding treatment of the fine surface of the welding by the traditional argon arc welding technology, which can greatly save the production cycle and production cost of the mold.

Product features

1. It can weld refractory materials and materials of different physical properties with a wide variety of weldable materials and good welding effect.

2, non-contact long-distance welding, welding more flexible, not easy to produce wear and deformation.

3, intelligent remote control parameters, digital or computer control to achieve automatic high-speed welding.

4, high standard and high configuration, electric lifting table, imported ceramic concentrating cavity, automatic shading system.

5, accurate positioning, small welding spot diameter, high welding energy, small heat affected area, can complete micro welding.

Applicable field

Suitable for digital products, mobile phones, toys, cars, motorcycles and other mold manufacturing and molding industries, used for all kinds of mold repair and welding and welding of all kinds of metal structural parts, gold and silver jewelry.

Technical parameters

Model | RFL-W-200 | RFL-W-300 | RFL-W-400 | |

Table size(mm) | 500x350 | 500x350 | 500x350 | |

Table load | 100KG | |||

Weight | 80kg | 90kg | 120kg | |

Power demand | 220V±10%/50Hz/60Hz / 380V±10%/50Hz/60Hz | |||

Spot size | 0.2-2.0mm | |||

Pulse width | 0.5-20ms | |||

Max average power | 200W | 300W | 400w | |

Pulse frequency | 0-100Hz | |||

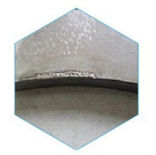

Sample display

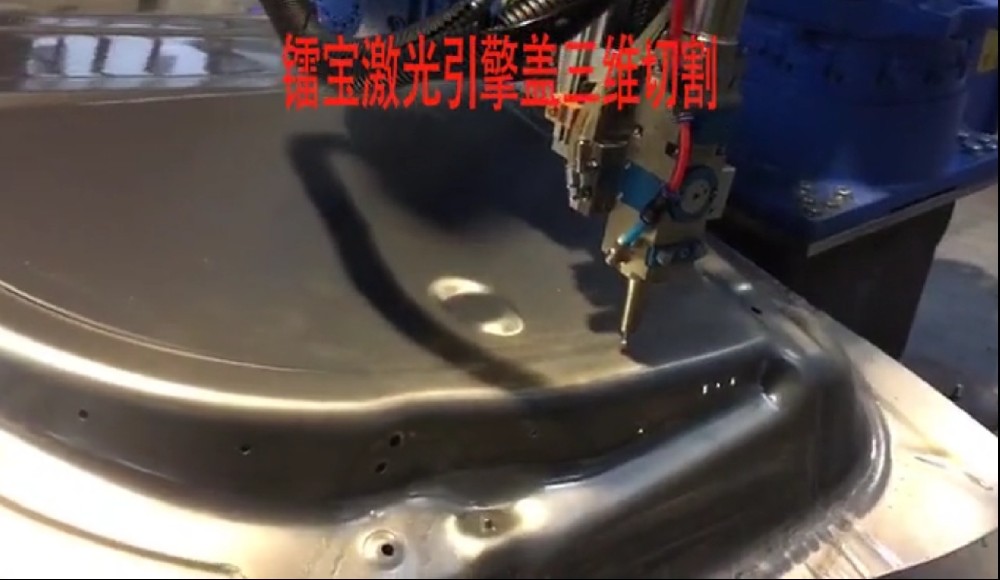

The principle of laser processing, the laser emitted by the laser generator after a series of processing, after the lens focus will be highly concentrated in a small range of energy, if the processing of the material of the laser absorption is good, then the irradiated area of the material will be rapidly heating up because of the absorption of the laser energy. Depending on the material properties (such as melting point, boiling point, temperature at which chemical changes occur), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, formation of oxides, discoloration, etc. This is how laser processing works.

Mainly for thin wall materials, precision parts welding

HC series laser mould welding machine is a special laser welding equipment specially tailored for the mould industry by Hengchuan laser. It is suitable for repairing laser welding equipment of small and medium-sized mould and mechanical parts. Laser mold welding is a professional application of laser local deposition welding technology in the field of tools and molds. Used for manufacturing error correction or manufacturing of special tools, or for repair of mold damage in production and repair of mold life extension. It is a new welding method, mainly for the welding of thin wall materials and precision parts.

Specially designed for the mold industry, used for precision mold repair, such as digital products, mobile phones, toys, cars, motorcycles and other mold manufacturing and molding industries. Through the repair of the mold, the original mold can be fully utilized, greatly saving the production cost and improving the work efficiency. This technology can be used to modify the mold design or size, reduce the cycle of product development.

Mold laser welding machine is a professional model specially tailored for mold industry, used for precision mold repair. Through the repair of the mold, not only can effectively repair trachoma, crack, collapse Angle and other small parts, but also can reuse the original mold, greatly save the production cost, greatly reduce the processing work after welding. Suitable for repairing and welding of precision laser components, welding of various metal structures and gold and silver jewelry.

Laser mold repair technology effectively deals with the welding and repair of all small parts, makes up for the deficiency of traditional argon arc welding technology in repairing the fine surface of welding, avoids the thermal strain and post-treatment of the two thresholds, greatly saving the production cycle of the mold.

Compared with the traditional mechanical processing, focused laser is like a very fine invisible cutter general, the surface of the local area of the object point by point "burn" off, it is not characterized by contact with the workpiece, does not produce mechanical extrusion or mechanical stress, so it will not change the physical properties of the processed items; Because the laser focused size is small, the heat affected area is small, and the processing is fine, it can complete some processes that cannot be achieved by conventional methods.

Mould laser welding machine adopts large LCD Chinese interface display, so that the operator is easier to learn and operate, the equipment also uses the shape programming function, to achieve multi-mode work, suitable for most materials of mould repair. Not only the heat affected area is small, the oxidation rate is low, but also there will be no trachoma, porosity and other phenomena. For the effect of repairing the mold, there will be no concave and convex phenomenon at the joint, and it will not lead to mold deformation.

Laser mold welding machine industrial touch screen control system, laser solder spot diameter is only 0.2mm~1.5mm; The heating area is small, the workpiece will not be deformed; After welding can be etched, does not affect the effect. Through the repair of the mold, the original mold can be fully utilized, greatly saving the production cost and improving the work efficiency.

The mold laser welding machine uses the double lamp ceramic reflection cavity imported from Britain, 200-400W power is optional, power is strong, pulse programmable and intelligent system management. Z axis of worktable can be moved up and down by electric focusing, controlled by industrial P machine. Equipment specification separate X/Y/Z axis 3d active moving table. Another optional rotary fixture (φ 80mm or φ 125mm optional). The monitoring system is microscope, red light and CCD. Equipped with external cooling system. The e mold laser welding machine uses the British imported double lamp ceramic reflection cavity, the power is strong, pulse.

The equipment is not only a special packaging equipment for battery production, but also can be used for welding of metal materials, such as relays, sensors, various electronic components and so on.

High electro-optical conversion rate, high energy efficiency ratio, no pollution. Green environmental protection, suitable for industrial production.

Up and down the table adopts electric lifting, three-dimensional movement, convenient for fast focusing.

Parameter adjustment is controlled by intelligent remote control, simple and fast operation.

Adopt advanced automatic shading system to avoid eye stimulation when working. The use of British imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life more than 8 million times.

The use of British imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life more than 8 million times.

The world's most advanced automatic shading system eliminates eye irritation during working hours.

Fast speed, large depth, small deformation

It can weld at room temperature or under special conditions, and the welding equipment is simple. For example, when a laser passes through an electromagnetic field, the beam does not deviate; Light can be welded in vacuum, air and certain gas environments, and can be welded through glass or materials transparent to the beam.

Can weld refractory materials such as titanium, quartz, etc., and can weld the opposite materials, the effect is good.

Micro welding is available. The laser beam can obtain a small spot after focusing, and can be precisely located, which can be applied to the assembly welding of micro and small workpiece produced by mass automation.

It can weld the parts that are difficult to reach, and carry out non-contact long-distance welding, with great flexibility

It can reduce the heat requirement to a low level, and the metallographic variation range of heat affected zone is small, and the deformation caused by heat conduction is also low.

The welding process parameters of 32mm plate thickness single channel welding are qualified after checking, which can reduce the welding time of thick plate and even eliminate the use of filler metal.

No electrodes are required and there are no concerns about electrode contamination or damage. And because it is not a contact welding process, the loss and deformation of the machine can be directly reduced to a low level;

Laser beam is easy to focus, alignment and guided by optical instruments, can be placed in the appropriate distance from the workpiece, and can be guided between the tools or obstacles around the workpiece, other welding rules because of the space restrictions and can not play;

The range of weldable materials is large, and various heterogeneous materials can be bonded with each other.

Easy to automate high-speed welding, also can be digital or computer control;

When welding thin material or thin diameter wire, it will not be as easy as arc welding to have the trouble of remelting;

Two metals with different physical properties (such as different electrical resistance) can be welded;

1. Specially designed for the mold industry, the introduction of German technology, the use of special structural design, suitable for all kinds of large, medium and small mold repair.

2. The use of British imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life more than 8 million times.

3. Adopt advanced automatic shading system to avoid eye stimulation during work.

4. The laser head can be rotated 360 degrees, and the whole light path part can be rotated 360 degrees, which is more convenient for positioning and welding of special-shaped objects.

5. Up and down the table adopts electric lifting, three-dimensional movement, convenient for fast focusing.

6. Parameter adjustment is controlled by intelligent remote control, simple and fast operation.

1. Small welding spot diameter, small heat affected zone, will not lead to precision mold deformation;

1. High welding energy, compared with the general welding machine can melt thicker welding wire, stable welding performance.

2, single laser pulse, waveform can be adjusted arbitrarily, to meet the welding process requirements of complex and special materials.

3, touch screen interface, easy to operate.

4, the use of British imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life more than 8 million times.

5, adopt the world's most advanced automatic shading system, eliminate the stimulation of eyes in working time.

6, laser head can rotate 360 degrees, the whole light path part can rotate 360 degrees, as well as up and down electric lifting, pushing back and forth, especially suitable for all kinds of large, medium and small mold repair.

7, parameter adjustment adopts intelligent remote control, simple and fast operation.

8, the table can be raised and lowered electrically, three-dimensional movement.

1, the use of imported ceramic concentrator, high reflectivity, strong energy, high temperature resistance, corrosion resistance, long service life; Note :400W with double light collector cavity

2, equipped with 1.5P special chiller, can meet the long time, high power welding stability is better; Note :400W with 3P chiller equipment introduction.

3, equipped with three-dimensional bearing base for electric lifting, table movement using precision ball screw and high precision straight guide light and flexible, accurate positioning, bearing up to 200 kg;

4, laser head can slide back and forth, manual lifting, laser head can be easily rotated 180 degrees, convenient repair welding any side;

5, equipped with gas protection system, effectively protect the product in the welding process is always protected by argon gas, keep the product color to ensure the welding quality.

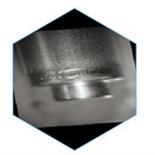

After welding, there will be no cracks, sand holes, scars, deformation, oxidation, suitable for mirror polishing, scratching, etching, the selection of corresponding welding materials and corresponding repair welding parameters can make the repair welding parts reach nearly HRC60° hardness.

Applicable materials: cold working high alloy steel, hot forging high alloy steel, nickel containing tool steel, copper alloy, beryllium copper, high toughness aluminum alloy and other metal materials.

Applicable industries: digital products, mobile phones, toys, cars, motorcycles and other mold manufacturing and molding industries.

Repair and weld cracks, collapsing angles, edges and sealing edges of hard materials such as molds, precision injection molding, die-casting, stamping and stainless steel; High accuracy, laser solder spot diameter is only 0.2mm~1.5mm; The heating area is small, the workpiece will not be deformed; After welding can be etched, does not affect the effect.

Mold laser repair machine at a temperature of 50-60 rockwell,

Can repair welding base materials are: all kinds of die steel, stainless steel, beryllium copper, precious metals and very hard materials.

CN

CN English

English